Textile Pollution: Imagine yourself browsing an online store, spotting a stylish t-shirt for just rupees 300. You add it to your cart, amazed at how affordable fashion has become. But let’s break it down: that low price is made possible by the textile hubs of South Asia like Bangladesh, India, and Pakistan. These countries have turned into global garment factories, producing clothes at a scale and speed that keeps costs down. The catch? This industrial boom is creating dangerous impact on the environment, especially through massive water waste and pollution. Rivers are turning toxic, groundwater is depleting, and communities are paying the price.

Yet, there’s a solution gaining traction: Zero Liquid Discharge (ZLD) technology. Let’s know why these textile hubs are struggling with water waste and how ZLD, backed by policy and global demand, could change the game.

The Powerhouse of Global Textiles

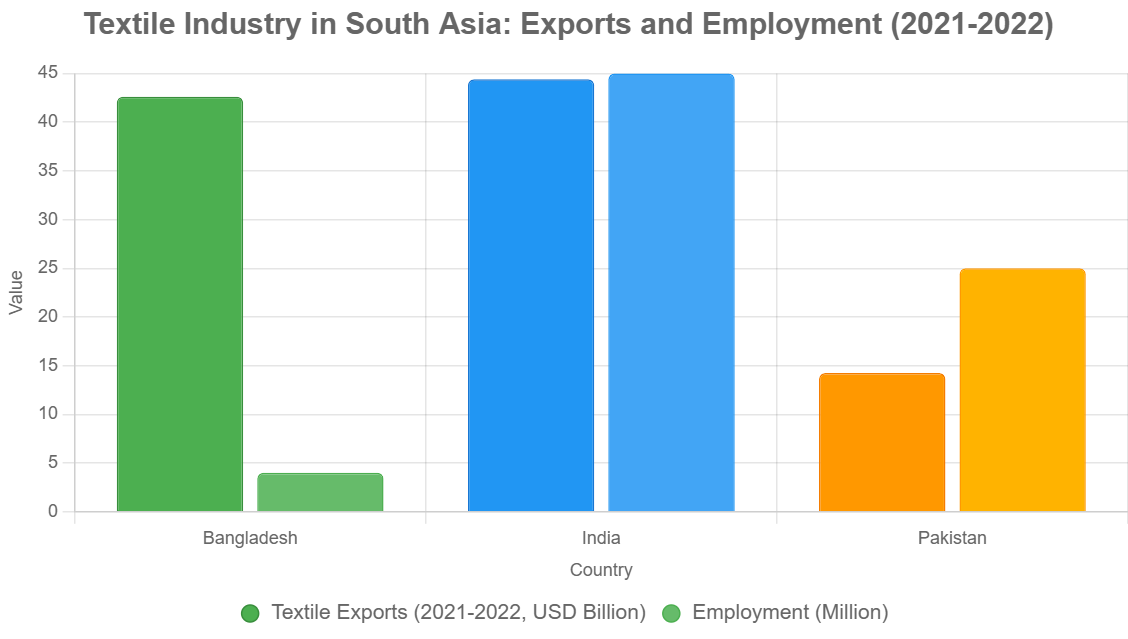

South Asia’s textile industry is a juggernaut, driving economic growth and providing millions of jobs. Here’s a snapshot of its scale:

-

Bangladesh: The second-largest apparel exporter globally, with garment exports worth $42.613 billion in 2021-2022. It employs over 4 million people, mostly women from rural areas, and accounts for 82% of the country’s export revenue.

-

India: One of the world’s oldest textile industries, contributing 2.3% to GDP and employing over 45 million people. In 2021, its market size was $223 billion, with exports reaching $44.4 billion in FY’22.

-

Pakistan: The largest manufacturing sector, contributing 8.5% to GDP and employing nearly 25 million people. Textile exports hit $14.24 billion in 2021-2022, with Pakistan ranking as the fourth-largest cotton producer globally.

These numbers show why textiles are the backbone of these economies. But what this really means is that the pressure to produce cheaply and quickly often overshadows environmental concerns, leading to significant water waste and pollution.

The Water Waste Crisis

Textile production is thirsty work. From growing cotton to dyeing fabrics, every step demands water lots of it. The dyeing and finishing processes are particularly water-intensive, and the wastewater they produce is often toxic. Here’s the situation in each country:

Bangladesh

-

Water Usage: On average, 164 litres of water are needed to dye one kilogram of textile material [4]. With millions of kilograms processed daily, the industry consumes an estimated 1,500 billion litres annually in garment factories and mills.

- Pollution: Factories often discharge untreated effluents into rivers, contaminating water with heavy metals, dyes, and chemicals like PFAS (perfluorinated alkyl substances). A 2024 study found PFAS levels in the Karnatali River near Dhaka at 300 times the EU’s proposed limit, posing risks to human health and ecosystems.

-

Impact: Farmers have seen crops fail due to polluted river water, and only 556 of 2,220 factories in the area have effluent treatment plants (ETPs), with fewer than 1% using them effectively.

India

-

Water Usage: The textile industry uses 425 million gallons of water daily, enough to supply a small city. In Tiruppur, a knitwear hub, dyeing units alone generate 96.1 million litres of wastewater daily.

-

Pollution: Until recently, Tiruppur’s Noyyal River was a stark example of textile pollution. The Orathupalayam dam, meant to store clean water, became a cesspool of effluents, with total dissolved solids (TDS) levels in river water ranging from 900 to 6,600 mg/L, far above safe limits. In Surat, groundwater near textile units in Kadodara is contaminated with dyes and chemicals, harming agriculture and causing skin disorders.

-

Impact: Over 20,000 hectares of farmland around Tiruppur were severely affected, making rice cultivation nearly impossible due to poor water quality.

Pakistan

-

Water Usage: Specific data is scarce, but as a major textile producer, Pakistan’s industry is known to be water-intensive. Textile dyeing alone contributes to 20% of global wastewater, and Pakistan’s share is significant.

-

Pollution: Untreated effluents are discharged into rivers and canals, polluting surface and groundwater with heavy metals and carcinogenic dyes like azo compounds. The Indus River, a lifeline for agriculture, is increasingly contaminated by textile waste.

-

Impact: Water scarcity is a growing concern, with the World Bank warning that Pakistan’s water resources could dwindle by 2025, exacerbated by industrial overuse.

Globally, the textile industry is responsible for about 20% of industrial water pollution, with dyeing and treatment processes generating much of the world’s wastewater. In South Asia, where water is already scarce, this pollution threatens ecosystems, public health, and economic stability.

What is ZLD (Zero Liquid Discharge)

Zero Liquid Discharge (ZLD) technology is a game-changer for tackling water waste. ZLD systems treat wastewater to recover nearly all water for reuse, converting the remaining contaminants into solid waste. This eliminates liquid discharge into the environment, reducing pollution and conserving water. Here’s how it’s making a difference:

Tiruppur’s Turnaround

Tiruppur, once infamous for polluting the Noyyal River, is now a model for sustainability. In 2011, the Madras High Court ordered the closure of 700 dyeing and bleaching units due to environmental damage. The response was swift:

-

ZLD Implementation: By 2015, 458 units connected to 18 Common Effluent Treatment Plants (CETPs) and 95 units with individual ETPs had adopted ZLD, recycling over 90% of wastewater.

-

Impact: Today, Tiruppur recycles 130 million liters of water daily, achieving a 96% reuse rate. Water quality in the Orathupalayam dam has improved, with fish returning to the area, a sign of ecological recovery.

-

Economic Benefits: ZLD has reduced freshwater demand by 50% in a decade, saving costs and boosting Tiruppur’s reputation as an eco-friendly textile hub.

Potential in Bangladesh and Pakistan

While Tiruppur leads, Bangladesh and Pakistan are starting to follow:

-

Bangladesh: The government has introduced ZLD regulations for the textile sector, recognizing the industry’s 1,500 million cubic meter water footprint. However, small and medium enterprises (SMEs) face challenges due to high costs and limited infrastructure.

-

Pakistan: Companies like Yunus Textiles and Interloop have installed large ETPs with up to 90% recycling efficiency, aiming for ZLD. Interloop’s use of nano-bubble technology has cut water use by 95%, showing what’s possible with innovation.

|

Region |

ZLD Status |

Water Recycled Daily (Million Litrds) |

Key Challenge |

|---|---|---|---|

|

Tiruppur |

Widely adopted since 2013 |

130 |

High initial costs |

|

Bangladesh |

Emerging regulations, limited uptake |

Not widely reported |

SME financial constraints |

|

Pakistan |

Adopted by large firms, scaling up |

Not widely reported |

Lack of widespread SME adoption |

Challenges and Opportunities

ZLD isn’t without hurdles. The technology is expensive, requiring significant upfront investment in reverse osmosis, evaporators, and reject management systems. For SMEs, which dominate South Asia’s textile sector, these costs can be prohibitive.

Additionally, managing the solid waste generated by ZLD remains a challenge. However, the benefits water conservation, reduced pollution, and compliance with global standards make it a worthwhile investment.

The Role of Policy and ESG-Driven Supply Chains

Governments and global brands have a critical role to play in scaling ZLD adoption:

-

Government Incentives: India’s Central Pollution Control Board (CPCB) mandated ZLD for textile units in water-stressed areas, backed by subsidies for CETPs. Similar policies in Bangladesh and Pakistan could accelerate progress. For example, Bangladesh’s recent ZLD regulation is a step forward, but enforcement and financial support are needed.

-

ESG Pressure: Global brands like Zara, H&M, and Primark, which source heavily from South Asia, are under scrutiny to meet ESG standards. Their demand for sustainable practices is pushing suppliers toward ZLD and other eco-friendly technologies. This market-driven pressure could be a catalyst for change.

-

Economic Upside: ZLD can recover valuable resources like salts and chemicals from wastewater, reducing production costs over time. In Tiruppur, this has helped maintain competitiveness despite initial expenses.

South Asia’s textile hubs have powered the global fashion industry, making affordable clothing a reality for millions. But the environmental cost particularly water waste and pollution cannot be ignored. Rivers like the Noyyal, Buriganga, and Indus bear the scars of untreated effluents, and communities are suffering.

ZLD offers a proven solution, as Tiruppur’s transformation shows, but its widespread adoption requires action from governments, brands, and the industry itself. By investing in ZLD, enforcing regulations, and aligning with ESG goals, South Asia can ensure that the price of a rupees 300 t-shirt doesn’t come at the expense of its water resources. The path to sustainability is challenging, but it’s one the region can’t afford to ignore.